Description

1. Application:

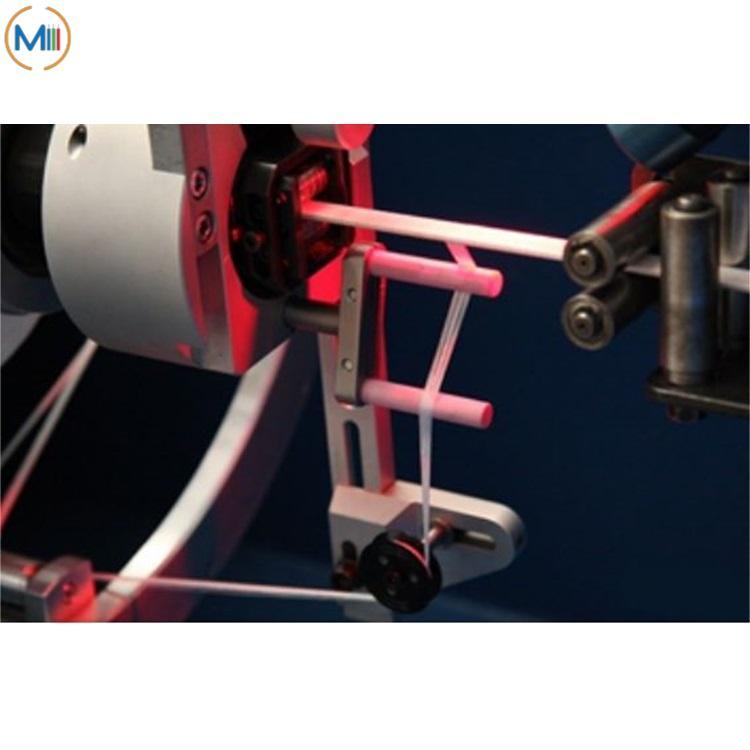

This production line is used for fiberglass double layer wrapped on nickel ally wire, with varnish coating and online sintering.

The finished wire can be widely used in military industrial,wind power generation,transformer,submersible pump,welding machine,electrical appliance and so on.

2. Parameter:

| Product range | Nickel ally wire 0.3 to 1.2mm

(section area from 0.07-1.13mm2) |

| Spool size | Pay-off: Φ400

Take-up Φ400 |

| Spooler tape | OD max 200mm

ID 76mm Height 100mm Thread density: tex 5.5-14.4. |

| Line speed | 1-10m/min

line speed= RPM * lay length /1000 |

| Taping head rotating speed | Max.3000RPM |

| Heating temperature | Max.800℃ |

| Wrapping pitch | 0.1-5.0mm, set the spinning pitch on touch screen

PLC auto trace and adjust spinning speed Pitch accuracy within 0.2mm. |

| Wrapping direction | S, Z both |

| Machine direction | Face the control panel, from left to right or from right to left |

| Machine color | Standard main body grey RAL7035, safety color yellow RAL1028; or customized. |

| Production process | Pay off PN400– -varnishing—fiberglass wrapping—varnishing—fiberglass wrapping—varnishing—drying in sintering oven—take up PN400 |

3. Advantage:

(1) Triple or single motorization drive system, high precise wrapping tension control, with special designed tape thread path; ensure precise taping lay length , overlap rate , and tension control. Film evenly wrapped on the conductor. Fiber glass uniformly distribute in a tape wrapped on the conductor, without fiber glass jump.

(2) Inductive heating together with high temperature heating oven. Ensure the sintering performance, increase line speed, save energy and labor. Cooling system use circulated water and air cooling, avoid film adhesion.

(3) The whole line controlled by PLC and HMl, production data set on HMl, HMl have receipt storage function.Easy to operate and easy to train new staff.

4. Delivery time: 90 working days

5. After-sell service:

The engineer will be dispatched as needed.

The buyer provides the engineer’s round-trip flight tickets, board, lodging, and security as well as each person of daily wage

6. Guarantee: 12 months since shipping date(exclude easily wearing part)

Click here to find out more about different types of Taping Machine