1. Introduction

In the modern wire and cable manufacturing industry, productivity, consistency, and automation have become essential for competitiveness. The Wire Drawing Machine — a crucial piece of equipment that reduces the diameter of metal wire by pulling it through a series of dies —must run continuously to ensure efficient production. However, one persistent challenge in traditional wire drawing operations is the manual spool change process.

When a take-up spool becomes full, production must stop so that operators can manually remove the full spool and replace it with an empty one. This interruption not only reduces overall productivity but also introduces risks of human error, uneven tension, and potential wire breakage.

To address these issues, Mentors have developed and implemented the Automatic Spool Change System. This innovation allows for seamless spool switching during continuous operation, significantly improving efficiency and product quality.

2.Overview of the Automatic Spool Change System

2.1 The automatic spool change system is an integrated solution designed to automatically replace a full wire spool with an empty one without stopping the wire drawing process.

2.2 The system typically consists of:

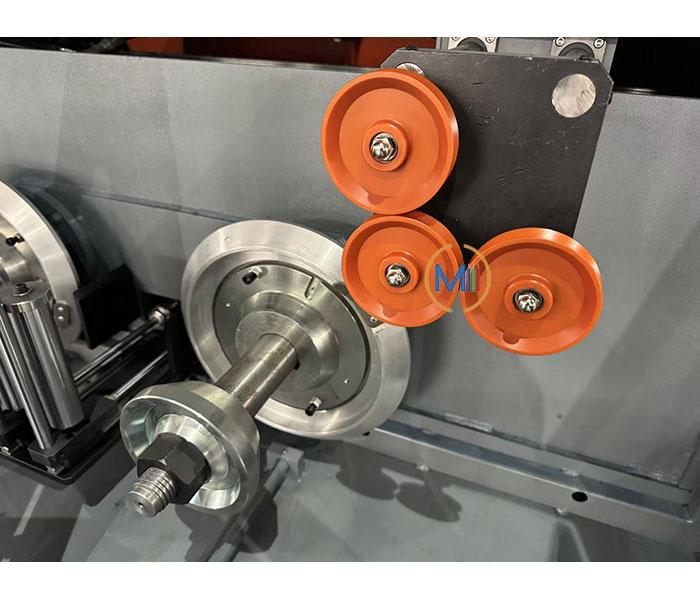

2.2.1 Spool change mechanism: includes a motorized arm, rotating plate, or servo-controlled spindle that physically removes and replaces spools.

2.2.2 Control unit: a PLC-based system that monitors spool status and coordinates all automatic movements.

2.2.3 Sensors and detectors: used to identify the spool’s filling level, detect wire speed, and send signals for spool replacement.

2.2.4 Pneumatic or servo devices: to drive mechanical movement precisely and safely.

2.3 When the system detects that the take-up spool is nearly full, it automatically prepares an empty spool and initiates a switch-over sequence.

2.4 The full spool is released and replaced with the empty one — all while maintaining continuous wire drawing.

2.5 This technology can be applied to both single Wire Drawing Machine and multi Wire Drawing Machine, including copper, aluminum, stainless steel, and welding wire production lines.

3.Key Advantages

3.1 Improved Production Efficiency

3.1.1 Automatic spool change eliminates downtime caused by manual replacement.

3.1.2 Traditional methods require stopping the machine for several minutes, while automatic systems perform the change in seconds — increasing output and reducing energy waste.

3.2 Reduced Labor Costs

3.2.1 Automation minimizes the need for manual intervention. Operators no longer have to monitor the spool continuously or perform time-consuming replacement tasks.

3.2.2 One operator can now manage multiple machines, reducing labor costs and improving operational efficiency.

3.3 Consistent Wire Quality

3.3.1 Manual spool changing can cause tension fluctuations or wire overlaps during the switch, which may lead to inconsistencies in wire diameter, elongation, or surface finish.

3.3.2 Automatic changeover ensures smooth transition and stable wire tension throughout the process, resulting in uniform quality and fewer defects.

3.4 Enhanced Safety

3.4.1 Manual spool replacement involves physical handling of heavy metal spools, posing risks of injury and accidents.

3.4.2 Automatic systems eliminate these risks by performing all movements mechanically and under safety controls, making the working environment much safer.

3.5 Intelligent Management

3.5.1 Modern systems can be integrated with PLC and touch-screen interfaces, enabling real-time monitoring, data collection, and automatic alarm reporting.

3.5.2 The operator can easily view production data, spool count, and system status, contributing to a smarter, more transparent production environment.

4.Working Process

4.1 Spool nearing full: As the take-up spool approaches its maximum capacity, sensors detect the wire diameter or spool diameter increase.

4.2 Signal detection: A full-spool signal is transmitted to the control unit, which prepares the empty spool.

4.3 Automatic switching: The system activates the mechanical arm or rotating mechanism to remove the full spool and position the empty one.

4.4 Continuous drawing: The wire drawing process continues without interruption, and the transition between spools occurs seamlessly.

4.5 Full spool transfer: The completed spool is labeled automatically or sent to the next processing station (such as annealing, tinning, or packing).

4.6 The entire cycle takes only a few seconds and does not require the operator to stop the machine or manually intervene.

5.Design and Control Features

5.1 Modular design: Each component, including the spool holder, motor system, and sensor assembly, can be replaced or maintained individually.

5.2 High-precision sensors: Laser or ultrasonic sensors detect spool diameter accurately to trigger the change command at the exact moment.

5.3 PLC-based control: The programmable logic controller ensures precise timing coordination between the drawing unit, capstan, and take-up system.

5.4 Synchronization with inverter drive: During spool change, the wire speed and tension are automatically adjusted through the inverter to maintain continuous flow.

5.5 Customizable options: The system can be tailored for different spool sizes, materials, and wire types, allowing flexibility for diverse production needs.

6.Operation and Maintenance Notes

6.1 Regularly inspect pneumatic and electrical systems.

6.2 Keep sensors clean to ensure accuracy.

6.3 Adjust spool detection sensitivity properly.

6.4 Perform manual calibration when installing or after maintenance.

6.5 Ensure emergency stop systems work reliably.

6.6 Proper operator training is also critical — understanding system logic, safety features, and emergency procedures ensures smooth daily operation.

7.Applications and Customer Feedback

7.1 Automatic spool change systems have been successfully applied in a wide range of wire production fields, including:

7.1.1 Copper wire for electrical and communication cables

7.1.2 Stainless steel wire for springs, ropes, and fasteners

7.1.3 Welding wire production lines

7.1.4 Aluminum wire for power cables and automotive harnesses

7.2 Customers who have implemented the system report 10–20% increases in production efficiency, along with significant reductions in manual workload and downtime.

7.3 The ability to run the machine continuously not only boosts capacity but also enhances overall process stability.

8.Conclusion

The automatic spool change system represents a major step forward in wire drawing automation. It eliminates downtime, enhances product stability, and ensures safer, smarter operations.

As smart manufacturing evolves, automatic spool change will become a standard feature of modern wire drawing machines — symbolizing the transition from manual labor to intelligent production, and shaping the future of efficient and sustainable wire manufacturing. If you want know more information about Wire Drawing Machine with Automatic Spool Change, you can click here.

NOTE:All rights reserved, Reprinting is prohibited without permission