1. Brief introduction:

The copper rod upcasting line (unit for shot as here below) is used to produce the long and bright oxygen-free copper rod. The induction melting furnace melts the copper cathode into liquid, the liquid keeps off the air by charcoal in case of oxidation. The holding furnace keeps the copper liquid temperature at 1150℃±10℃, the casting machine crystallizes the copper liquid in a crystallizer quickly, then continuously produces copper rods, then the final product will be finished through the double head take-up machine and other accessory equipment.

The unit is composed of a power frequency induction furnace, copper rod continuous casting machine, rack of directive wheels, tension device, two-stroke coiler, cooling system, electric system, feeding system and measure temperature system, and so on.

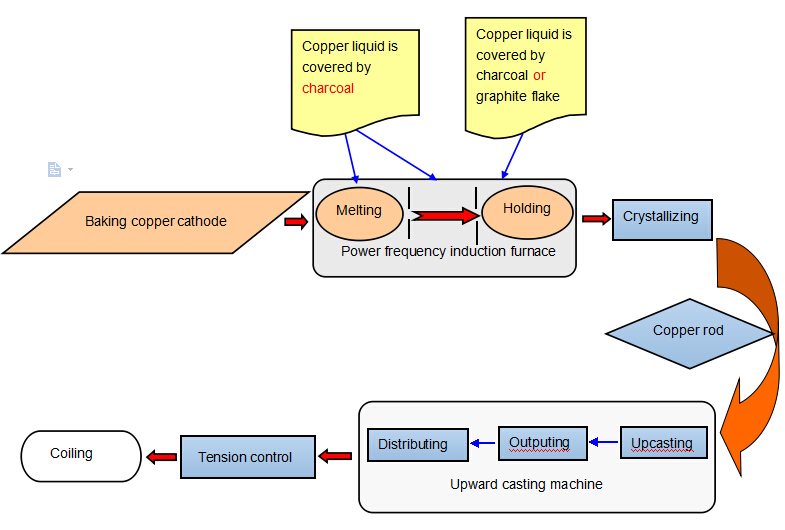

2. Copper Rod Manufacturing Process:

Put copper cathode over the furnace by the lifting system for baking→Adjust the feeding speed according to the casting speed. Feed the copper cathode into the melting furnace for melting (charcoal to be used for avoiding oxidization) → copper liquid flows into the transition part (charcoal is still needed to avoid oxidization) → Copper liquid flows into the holding furnace → Copper Liquid flows into the crystallizer to be copper rods → copper rods enter into traction device for upward movement → Go through the output frame →copper rods go through the distribution frame (to separate each rod) → copper rods go through the tension frame ( to control the take-up speed) → copper rods go through the take-up machine, for coiling → Next process.

3. Introduction of each part:

3.1 Power frequency induction furnace:

The frequency induction furnace includes the furnace body, furnace frame, and inductor.

The shell of the furnace is made of welded steel, inside part is made of casted refractory brick and quarts of sand. The furnace frame is used for propping up the whole furnace, it is fastened on the foundation by ground bolt, inductor composed of coil, water jacket, iron core, and copper channel. Among them, the melting furnace has two large melting channels, which can melt copper quickly and heat evenly, which is easier to meet the process requirements. The holding furnace is relatively long, and two melting channels are used to control the temperature, and double thermocouples are used to ensure that the temperature of the holding furnace is consistent, so as to ensure the stable quality of the billet.

3.2 Copper rod continuous casting machine:

The continuous casting machine is the main part to realize the continuous casting which includes the traction system, the liquid level tracking system, and the crystallizer, the structure is a gantry with four pillars.

The traction system includes two units of servo motor, reducer, and traction rolling wheel, it could take 0-800 times high-speed interval motion and make the copper rod come up through the traction rolling wheel.

The automatic level track system could ensure that the crystallizer is in a stable depth in the copper liquid, and make sure the production is continuous.

The crystallizer could freeze the copper quickly into a solid state by cooling it and realizing the heat exchange, each crystallizer can be changed and be controlled separately without any influence of other crystallizers’ normal working.

The crystallizer is installed with a quick lifting device, and the replacement of the crystallizer is fast and safe, especially in emergency situations.

3.3 Output frame:

The output frame is set up on the upper part of the rod-casting machine. It includes the platform, the support, the vertical guide wheel, and the roller. It separates and feeds the casted rods into each double-head take-up machine without influencing each other.

3.4 Tension frame:

The take-up synchronizing device is a device that is set up between the output frame and the double-head take-up machine. The guide wheel frame can slide up and down on the linear guide rail, and the copper rod controls the speed of the double-head wire take-up machine through the height of the guide wheel frame.

This can achieve high-precision, high-sensitivity control of the speed of the take-up, and also provides a reliable signal for fully automatic control.

3.5 Double-head take-up machine:

The double-head take-up machine includes the traction roller, the coiling device, and the coiling plate. Each group of double-head wire take-up machines is driven by four motors to rewind two sets of devices to rewind two copper rods, and the maximum coil weight is 4 tons. The deceleration motor is directly connected to form a coil, and the frequency conversion automatically arranges the rods.

3.6 Water Cooling System:

The water cooling system is an independent water recycling system that supplies the 0.2-0.4 Mpa cooling water for the crystallizer, the water jacket, and the coil. It includes one water pool, a water pump, pipelines, and a cooling tower. It ensures that the inlet water temperature is around 20-35℃, and the flow rate is at a suitable level. To ensure a good heat-exchanging effect needs to prepare the water-softening device.

3.7 Electric control system:

The electric control system includes the power system and controlling system. The power system supplies the power to each inductor through several power panels. The control system assures the normal producing, recording, and displaying of the data. The detailed recording and displaying information are inductor voltage, current, furnace temperature, and water temperature. (including the crystallizer water temperature), traction speed and traction distance etc.)

3.8 Feeding system:

The feeding system feeds the whole piece of the copper cathode by the electric hoist. It assures that the copper cathodes are supplied to the melting furnace continuously.

3.9 Temperature Testing System:

The temperature measurement system consists of two parts: copper liquid temperature and cooling water temperature. The measurement results can be displayed on the paperless recorder and industrial control panel respectively which to achieve production monitoring of the equipment.

The above is something about the copper rod manufacturing Process and each part’s introduction, if you have more ideas, please contact us. And more detailed information about our Copper Rod Upcasting Machine, you can click here:https://www.mentorsmachinery.com/8mm-copper-rod-making-machine/

NOTE: All rights reserved, Reprinting is prohibited without permission.