First of all, before answering this question, let us find out what characteristics they have. Normally for Copper Rod Breakdown Machine, there are mainly two types in the market. They are gear drive and individual motor drive.

1.Copper Rod Breakdown Machine with Individual Drives

1.1 Main Spec Forms

| SY-LSD450 Individual Motor Controlled ROD Breakdown Machine | ||||

| Machine type | LSD450/13 | LSD450/11 | LSD450/9 | |

| Drawing Capstan Dia.(mm) | 450 | 450 | 450 | |

| Max. Die No. | 13 | 11 | 9 | |

| Inlet Dia.(mm) | Copper | 8 | ||

| AL, Al Alloy | 9.5 | |||

| Outlet Dia. (mm) | Copper | 1.2-4.2 | 1.5-4.2 | 2.0-4.2 |

| AL, Al Alloy | 1.7-5.0 | 2.2-5.0 | 2.8-5.0 | |

| Max.Drawing Speed (MAX) (m/s) | 25 | 25 | 20 | |

| Single Motor Power (KW) | 37 / 55 (AC) | |||

| Capstan Arrangement | Horizontal Tandem Layout | |||

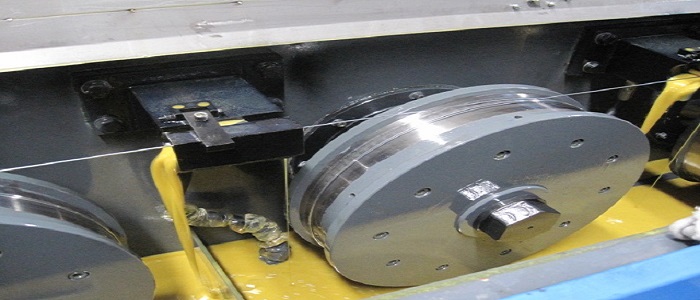

| Lubrication Type | Full Immersion | |||

| Take-up Type (Optional) | Double Take-up/ Single Take-up / Coiler | |||

| Optional Equipment for copper wire | Horizontal continuous annealing | |||

1.2 Characteristics:

1-1 Each capstan is run by individual.The mechanical elongation of each shaft is variable, which can realize the production of all sizes by one set of dies and reduces the dies cost. Drum shaft is driven by an independent AC motor, and the multi-shaft is connected to the reducer. Motors can be interchanged with the same model, each shaft can be selected to work or not. The efficiency factor of each motor exceeds the high-efficiency IE2 standard, which is highly energy-efficient.

1-2 Drawing reduction ratio can be adjustable according to different raw material. Like T1 to T3 Copper Rod, submarine cable and New Energy Automotive Cable.

1-3 Door up and down automatically make wire threading easily.

1-4 Quick die change system.

1-5 Full immersion guarantee the wire’s cooling and lubrication.

2.Rod Breakdown Machine with Gear Drive

2.1 Main Spec Form

| Item | LHD450/13 | LHD450/11 | LHD450/9 |

| Inlet Wire Dia.(mm) | 8 | 8 | 8 |

| Outlet Wire Dia.(mm) | 1.2~4.0 | 1.5~4.0 | 2.0~4.0 |

| Max Die No. | 13 | 11 | 9 |

| Max. Line Speed(mm) | 25 | 22 | 20 |

| Main Motor(KW) | 280 | 280 | 280 |

| Drawing Capstan | Coated with tungsten carbide | ||

| Take-up type | Dual-spool take-up, drop coiler, compact coiler | ||

| Lubrication Type | Immersion and spraying | ||

2.2 Characteristics:

2-1 low investment

2-2 Horizontal structure, operate easily.

2-3 Fast die change system keep high efficiency when produce different diameter.

And dies quantity decrease a lot at the same time.

2-4 There is a small inclination between the axis of the drawing capstans and the gear box transmission axis.This special design can avoid the wire from overlapping with each other on the drawing capstan surface,while maintaining a straight path from the first capstan up to the last one.

3 How to Choose suitable Copper Rod Breakdown Machine?

3-1 The advantages and disadvantages of Gear Type Copper Rod Breakdown Machine.

3.1.1 The cost of Gear Type Copper Rod Breakdown Machine is much lower than Copper Rod Breakdown Machine with Individual Drives.

3.1.2 Since gear type transmission, noise is larger than individual drives type

3.1.3 After 10 year, usually gear need to be replaced. If supplier product upgrade or company closed, that will be a big problem for long time maintenance.

3-2 The advantages and disadvantages of Copper Rod Breakdown Machine with Individual Drives.

3.2.1 If need produce lots of different raw material, use this type is suitable. Since Drawing reduction ratio can be adjustable flexibly.

3.2.2 Low maintenance cost. Motors can be interchanged with the same model.Motors and reducers are standard parts and can be bought on the market easily. Buyers have low reliance on the supplier.

3.2.3 Each shaft can be selected to work or not,energy savings of up to 20% by multimotor drive technology. additional energy saving due to the elimination of gears in the fast section – no gear losses.

3.2.4 The cost is much higher than Gear Type Copper Rod Breakdown Machine

Briefly, when budget is enough and need produce lost of different raw material, then choose Copper Rod Breakdown Machine with Individual Drives is better. If not, gear type Copper Rod Breakdown Machine is suitable.

After you know all details, if it is still difficult to decide, you can discuss more with us.

NOTE: All rights reserved, Reprinting is prohibited without permission.