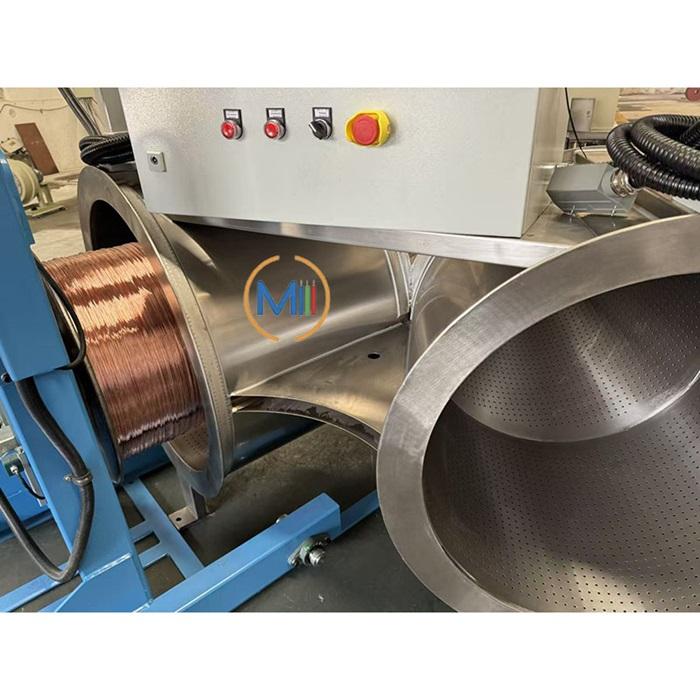

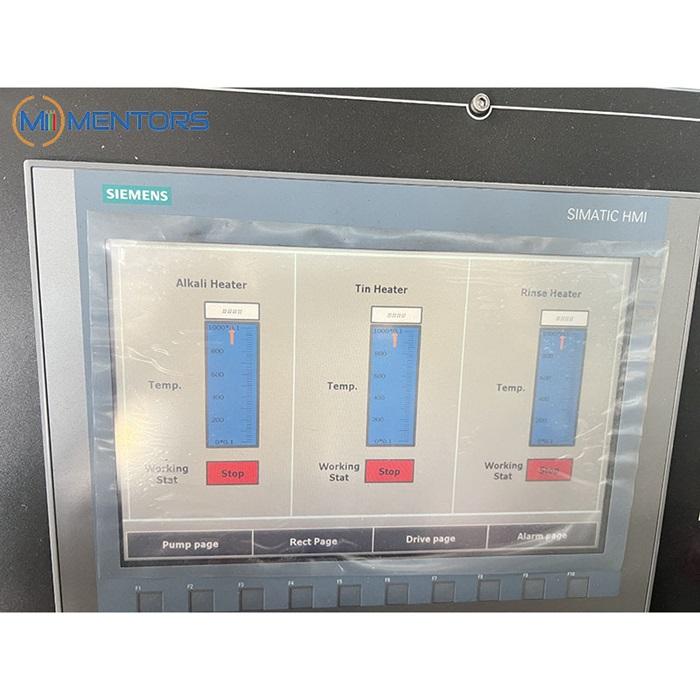

Tin Electroplating Machine for Copper Wire

Tin Electroplating Machine for Copper Wire is a new high-quality equipment, which is mainly used for tinning on the production of bare copper conductors.

Main feature:

1)Coating material: Tin

2)Coating thickness: 1-20um

3)Inlet wire diameter: 1.2-2.6mm

4)Production speed: 10m/s (Max.production speed)