Single-core cable is a commonly used electrical transmission device, which consists of an inner conductor and an outer insulating material. Compared with multi-core cables, single-core cables have their own unique characteristics and functions. Today, Mentors will show you the process flow and application of common single-core cables, and analyze them through examples. Power transmission and electrical equipment play a vital role in modern society. In this information age, cables are indispensable as transmission channels for electric current. However, in practical applications, we often use single-core cables, so what is its process?

First, there are three main types of single-core conductors: no twisting required, 7-wire twisting, and multi-wire twisting. The following are the instructions for single-core 1.5-6mm² cables.

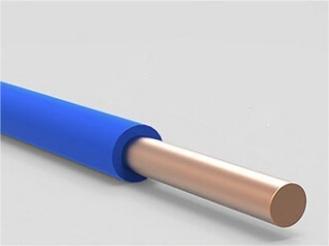

1.1 No twisting required conductor

| Nominal Conductor Area(mm²) | Number strands/Diameter

per strand |

|

|

|

| 1.5 | CU 1×1.38 |

| 2.5 | CU 1×1.78 |

| 4 | CU 1×2.25 |

| 6 | CU 1×2.76 |

Process Step 1: Intermediate Wire Drawing Machine with Annealing

Process Step 2: Cable extruder

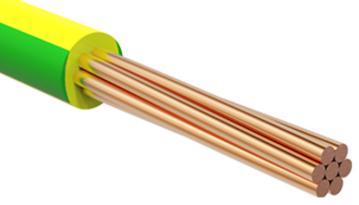

1.2 7-wire twisting conductor

| Nominal Conductor Area(mm²) | Number strands/Diameter

per strand |

|

|

|

| 1.5 | CU 7×0.53 |

| 2.5 | CU 7×0.67 |

| 4 | CU 7×0.85 |

| 6 | CU 7×1.04 |

Process Step 1: Intermediate Wire Drawing Machine with Annealing

Process Step 2: Double Twist Bunching Machine

Process Step 3: Cable extruder

1.3 Multi-wire twisting conductor

| Nominal Conductor Area(mm²) | Number strands/Diameter

per strand |

|

|

|

| 1.5 | CU 30×0.25 |

| 2.5 | CU 50×0.25 |

| 4 | CU 56×0.30 |

| 6 | CU 80×0.30 |

Process Step 1: Intermediate Wire Drawing Machine with Annealing

Process Step 2: Fine Wire Drawing Machine with Annealing

Process Step 3: Double Twist Bunching Machine

Process Step 4: Cable extruder

2. Feature:

2.1 Flexibility: Single-core cables are wrapped in insulating materials, so they have a certain degree of softness and bendability. This makes it easy to pass through narrow spaces or curved paths during installation.

2.2 Anti-interference ability: Compared with multi-core cables, single-core cables are not easily affected by external interference, and the transmission signal is more stable and reliable.

2.3 Cost saving: Since single-core cables have a simple structure and a relatively easy manufacturing process, they can be used more economically and efficiently in some applications.

3. Function:

3.1 Power transmission: Single-core cables are mainly used to transmit electrical energy from power sources such as generators and transformers to various terminal devices, such as household appliances and industrial equipment. Its internal conductor can effectively transmit current to meet the equipment’s demand for electrical energy.

3.2 Signal transmission: Single-core cables are also widely used in signal transmission fields, such as security systems and communication equipment. The signals transmitted by single-core cables can realize various control and communication functions to meet the needs of different scenarios.

3.3 Lighting applications: In the field of lighting, single-core cables are often used to connect lamps and power sources to achieve the normal operation of lighting equipment. Its design structure and material selection have good conductivity and insulation properties, which can ensure the normal operation of the lighting system.

4. High temperature environment application:

Because single-core cables have good conductivity and insulation properties and are not easily affected by external interference, they are widely used in high temperature environments. For example, the power supply lines of industrial high-temperature furnaces, electric furnaces and other equipment usually use single-core cables.

Taking home lighting as an example, we can further explain the characteristics and functions of single-core cables. In home lighting, single-core cables are used to connect lamps and power sources to transmit electrical energy to achieve lighting functions. They are characterized by simple structure and strong flexibility. They can be easily hidden in walls or ceilings without taking up too much space. Single-core cables have strong anti-interference ability, which avoids signal interference and ensures the stable operation of the lighting system. In addition, the manufacturing cost of single-core cables is relatively low, which reduces the investment cost of home lighting systems.

As a common electrical transmission device, single-core cable plays an important role in power transmission and signal transmission. It has the characteristics of simple structure, strong flexibility, strong anti-interference ability and low cost. In practical applications, you can choose the appropriate single-core cable according to specific needs to meet the electrical transmission needs in various scenarios.

If you also want to produce single-core cables, Welcome to consult Mentors: sunman@mentorsmachinery.com

NOTE: All rights reserved, Reprinting is prohibited without permission.